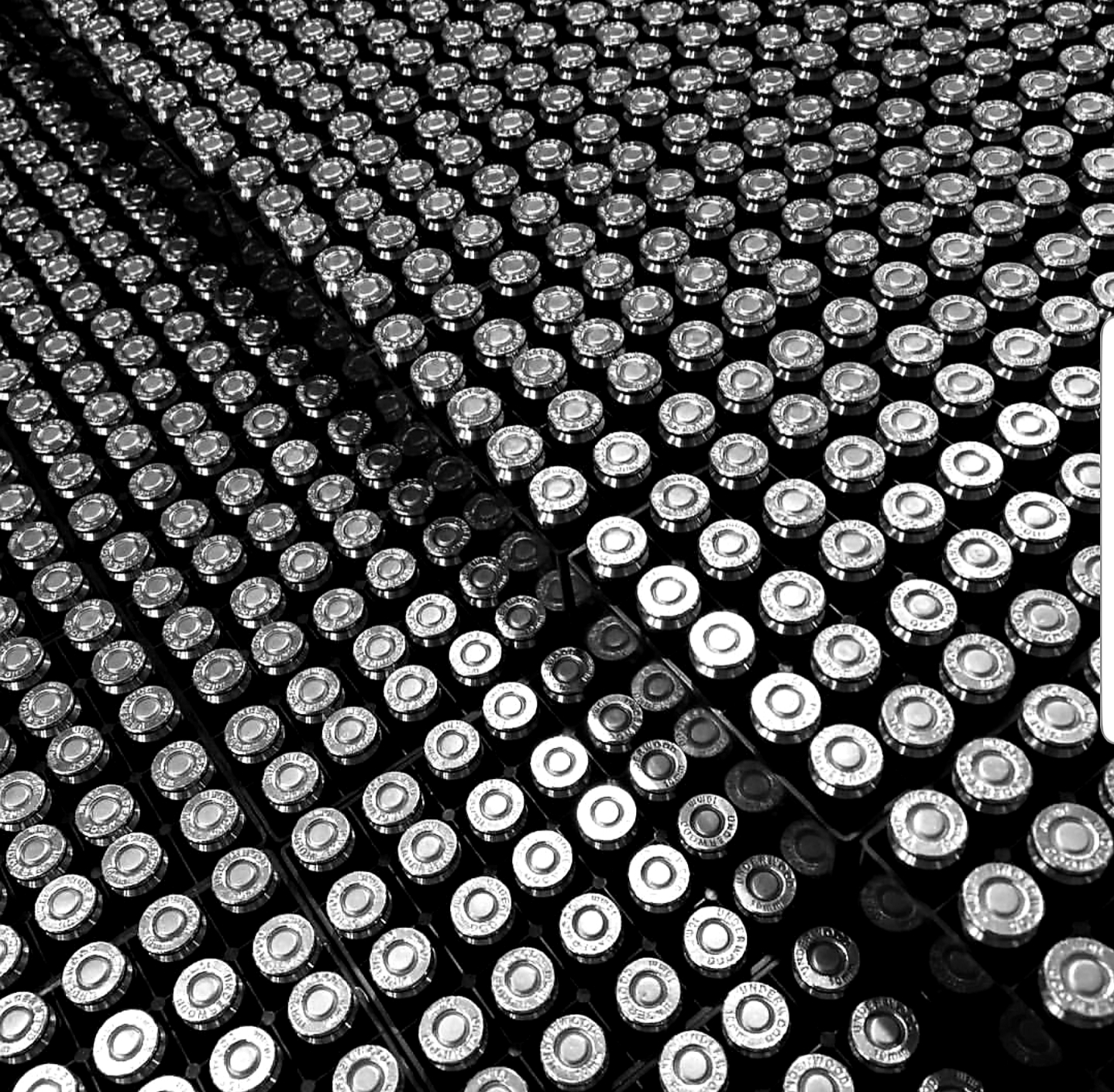

Εάν έχετε περιηγηθεί στις σελίδες μας, πιθανότατα έχετε παρατηρήσει μια σειρά από αμυντικά πυρομαχικά που οι κάλυκες τους μοιάζουν με καθρέφτη. Τα φυσίγγια αυτά δεν είναι κατασκευασμένα από αλουμίνιο, αυτό που βλέπετε είναι επινικελωμένοι ορειχάλκινοι κάλυκες υψηλής ποιότητας που επιλέγει η Underwood για τα αμυντικά πυρομαχικά της.

Το νικέλιο έχει χαμηλότερο συντελεστή τριβής από τον ορείχαλκο, που είναι απλώς ο επιστημονικός τρόπος να πούμε ότι είναι πιο λείο. Για αυτούς τους λόγους, η όπλιση και εξόλκυση του φυσιγγίου είναι πιο ομαλή. Εάν μια μέρα η ζωή σας μπορεί να εξαρτηθεί από αυτό, δεν είναι κακή ιδέα να προτιμάτε φυσίγγια που διαθέτουν αυτήν την τεχνολογία, καθώς φέρνει κάθε πλεονέκτημα με το μέρος σας.

Τα επινικελωμένα φυσίγγια αντιστέκονται επίσης στη διάβρωση καλύτερα από τον ορείχαλκο, κάτι που προκαλεί ανησυχία για πυρομαχικά που ενδέχεται να εκτίθενται στις καιρικές συνθήκες για μεγάλο χρονικό διάστημα. Καθώς αυτά τα πυρομαχικά πρόκειται να περάσουν μια παρατεταμένη χρονική περίοδο έξω στα στοιχεία, αυτά θα πρέπει να αντέξουν τις αλλαγές θερμοκρασίας.

Ο τρίτος λόγος για να επιλέξετε επινικελωμένους κάλυκες είναι η βελτιωμένη ορατότητά τους σε συνθήκες χαμηλού φωτισμού. Οι επινικελωμένοι ορειχάλκινοι κάλυκες εχουν καλύτερες ιδιότητες ανάκλασης σε σύγκριση με τους κανονικούς ορειχάλκινους και διευκολύνουν την εκτέλεση ελέγχων του θαλάμου του όπλου σας σε συνθήκες χαμηλού φωτισμού.

Κλείνοντας, η επινικελίωση είναι για πολύ περισσότερα από μια απλή εμφάνιση. Εάν σκοπεύετε να αποθηκεύσετε τα φυσίγγια μακροπρόθεσμα, ή να τα επαναχρησιμοποιήσετε αφού έχουν επηρεαστεί από τις καιρικές συνθήκες, σκεφτείτε σοβαρά την εκδοχή να προτιμήσετε φυσίγγια με επικάλυψη νικελίου στον κάλυκα τους.